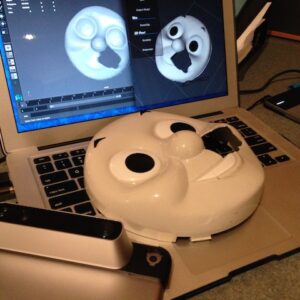

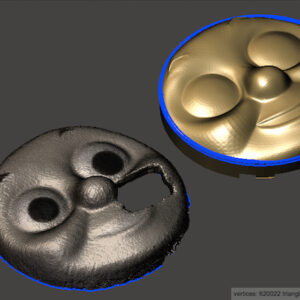

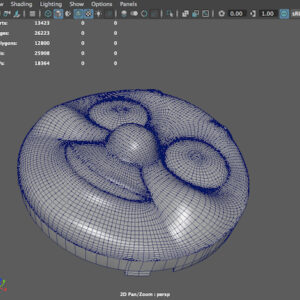

my recent home project was fixing a broken toy parts that no longer available. will be primed & painted. over engineering just to fix a toy? no, this is my small contribution reducing landfill till I absolutely have to let go. My very first print practice piece trashcan hinge is still serving the purpose. Used Straucture Sensor for scanning broken parts, re-modeled in Maya and printed in Ultimaker.

as long as remember from my childhood, Japan has volunteer based toy repair services (Toy Hospital) and I grew up being taught to repair if I can. i cannot fix everything but i like the problem solving aspect of this process. also running a large print job is very satisfactory at the end 🙂

| Material | Ultimaker Blue PLA Translucent |

| Print time | Front: 23 hrs, Attachment Part:4 hrs |

| Base | Brim |

| Layer Height | 0.1mm (equivalent of UM2 “Normal” quality) |

| Shell Thickness | 0.8mm |

| Fill Density | 20% |

| Print speed | 50 |

| Size | 18.75cm diameter |